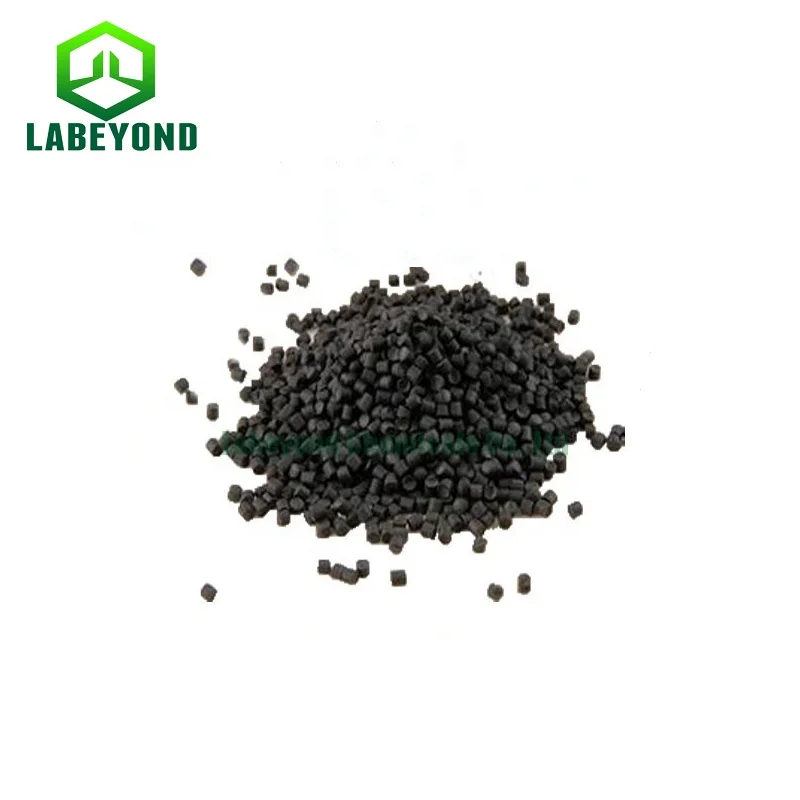

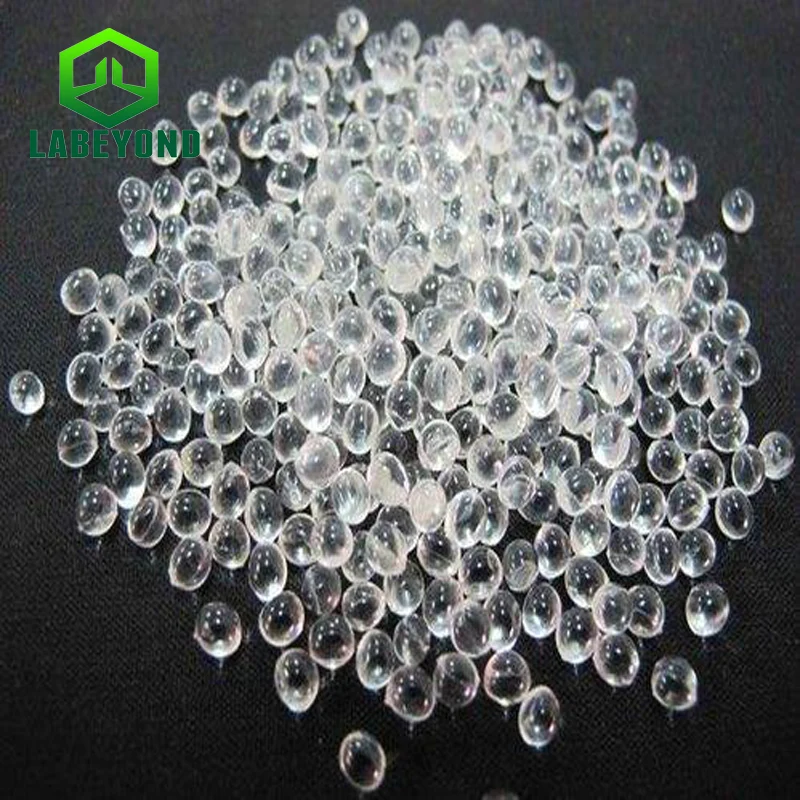

polyamide-imide

Quick Details Port: shanghai Payment Terms: L/C,T/T,Western Union Supply Ability: 3 Ton/Tons per Month Product name: PAI Grade: Injection Grade Feature: High Temperature Resistance Application: general purpose Appearance: Granular Delivery Detail: 4-6 days after receive the payment Packaging Detail: 25kgs/bag, 1ton/pallet Product Description PAI (polyamide-imide)combines the exceptional performance of thermoset polyimides with the melt-processing advantage of thermoplastics. Wear-resistance grades offer unsurpassed performance in both dry and lubricated environments. High-strength grades retain their toughness, high strength and high stiffness up to 275°C (525°F), making PAI the industry's highest performing thermoplastic. Its broad chemical resistance includes strong acids and most organics. PAI exhibits greater compressive strength and higher impact resistance than most advanced engineering plastics. High creep resistance and an extremely low coefficient of linear thermal expansion (CLTE) provide excellent dimensional stability. Company Information Our Services