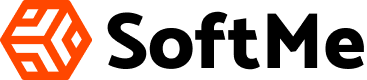

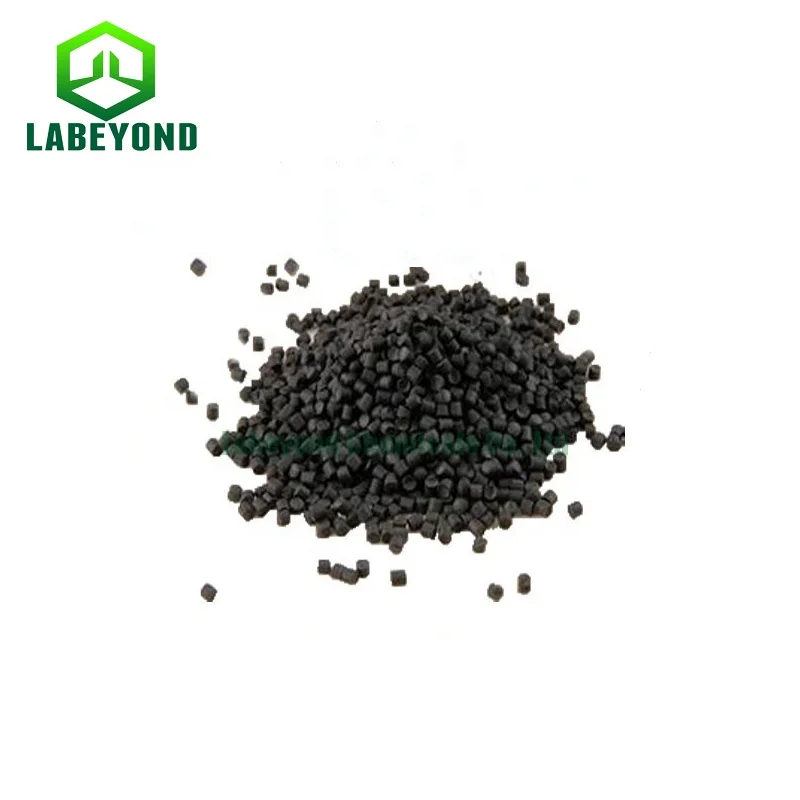

biodegradable plastic raw material PHA resin PHA pellets for plastic bag

Quick Details Port: qingdao Payment Terms: L/C,T/T,Western Union Supply Ability: 300 Ton/Tons per Month Product name: PHA resin Grade: injection and extrusion Application: film,bottle Appearance: pellets Delivery Detail: 4-6 days after receive the payment Packaging Detail: 25kgs/bag, 1ton/pallet Product Description biodegradable plastic resin PHA resin PHA pellets for plastic bag PHA resin PHA resin is recognized as the 100% biodegradable polymer materials, which can be degraded through composting process like PLA. But also it can be completely degraded into CO2 and H2O just burying in soil, or discarding into waste water or marine water after 3 to 6 months without any composting process. Compared with other plastic products of the same functions, the entire life cycle of PHA resin products uses less energy sources and less emissionof CO2. Our vision is to promote the applications of fully biodegradable materials in people’s lives as well as to reduce the depletion of oil resources, so as to effectively decreasing the green gas emission an making great contributions to sustainable development of our society. PHA resin Applications 1. Biodegradable material for injection, extrusion, foaming, blowing 2. Modifying additives of other degradable materials, such as PLA, starch, PBS, etc. 3. […]