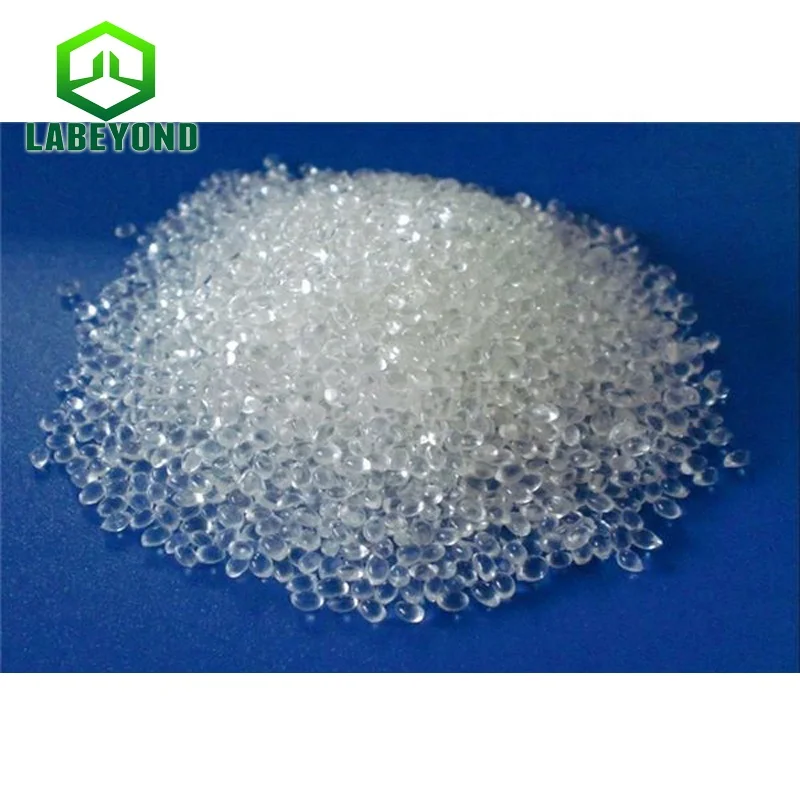

PLA resin for research

Quick Details Port: qingdao Payment Terms: L/C,T/T,Western Union Supply Ability: 300 Ton/Tons per Month Product name: polylactic acid Material: PLA Grade: REVODE 195 Application: film,filament Appearance: Granular Delivery Detail: 4-6 days after receive the payment Packaging Detail: 25kgs/bag, 1ton/pallet Product Description Best price ! VIRGIN PLA plastic pellet for 3d printing filament PLA takes annually renewable resources – corn, cassava and other plants as raw material. After fermentation by microorganisms, lactic acid will be extracted, then PLA will be produced through a process of refining, dehydration polymerization, high temperature pyrolysis and final polymerization. PLA has excellent biodegradable property. After disposal, within one year, it can be degraded into carbon dioxide and water by microorganisms in the soil, and do no harm to our environment. PLA is a kind of aliphatic polyester with basic characteristics of general micromolecule materials. PLA has good machanical properties, low shrinkage, and is competent to the application of most synthetic plastics, also it's widely used in the production of package materials, disposable tableware, household electrical appliance shell, fiber, 3D supplies etc. Because PLA derives from renewable plant resoures but not the petroleum-based traditional plastics, so it can truely realize energy-saving and enviromental protection, and PLA […]