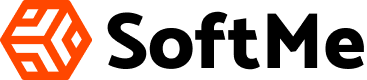

PLA powder for student with best price

Quick Details Port: shanghai Payment Terms: L/C,D/A,D/P,T/T,Western Union,MoneyGram Supply Ability: 10000 Kilogram/Kilograms per Month Product Name: PLA powder Appearance: Powder Delivery Detail: within 3 days after payment Packaging Detail: 1kg/bag or according to to your requirements Description Product Name:PLA powder Appearance:White powder Size: 100mesh , 150 mesh Service we can provide:1. provide costomers with "one-stop"packaging service,from manufacture ,research,development,production,export and so on2. Quality control, before shipment.3. Prompt shipment with professional documents4. Packing as your request, with photo before shipment5.Mix and different products in ONE PCL,increase the working efficiency for customers.6.We can export from many China main ports,convenient for the customes provide logistics services.7.. gold members with high credit guarantee. Our Advantages:Full experience of large numbers containers loading in Chinese sea portFast shipent by reputed shipping linePacking with pallet as buyer's special requestCargoes together with container sales service availableCargoes photo before and after loading into containerRaw materials from Chinese origin Professional Loading:1.We will provide you with professional loading2.We have one team supervise uploading the materials. We will check the container, the packages3.Every step, taking pictures and make records.4.we will make a complete Loading Report for our customer of each shipment.